فاینکس فرصت تبادل دانش وگسترش سواد مالی

حامد سلطانی نژاد درباره دهمین نمایشگاه بورس، بانک و بیمه (فاینکس ۲۰۱۷) با تاکید بر اینکه برگزاری چنین گردهماییهایی برای بازار سرمایه ایران ضروری است، گفت: در بازار سرمایه توسط برخی از نهادها دستاوردهایی به وجود می آید که پیش نیاز فعالیت برخی نهادهای دیگراست، بنابراین برگزاری این نمایشگاه فرصت مناسبی است تا دستاوردهای مالی و فنی محصولات تازه ای که تولید شده به فعالان بازار معرفی شود تا آن ها هم بتوانند با هم افزایی با سایر فعالان بازار محصولات جدیدتری را برای استفاده همگان در بازار سرمایه ارائه دهند.

وی اظهار داشت : از سوی دیگر این نمایشگاه می تواند یک نقطه قرار باشد برای فعالان مالی که هر ساله طبق رسمی که در همه صنوف و صنعت ها وجود دارد دور هم جمع می شوند و با هم مذاکره می کنند ، بنابراین برگزاری این نمایشگاه فرصتی به وجود می آورد تا تمامی فعالان حوزه بازار سرمایه کشور با همفکری یکدیگر نقشه راه آینده ای را ترسیم کنند که به تناسب آن نقش هر یک از آنها در پیشرفت بازار سرمایه موثر باشد و از این مسیر برنامه ریزی بهتری برای رسیدن به اهدافشان داشته باشند.

وی ادامه داد: این نمایشگاه همچنین فرصتی خواهد برای این که عموم مردم عزیز کشورمان نیز در جهت آشنایی با بازار سرمایه آشنایی بیشتری پیدا کنند، چرا که بازار سرمایه با وجود فعالیت هایی که طی چند سال اخیر داشته، اما همچنان از برخی جوانب برای مردم ناشناخته است، بنابراین، نمایشگاه فاینکس فرصت آشنایی مناسبی برای آن ها نیز خواد بود، همچنین امکانات دیگر بازار سرمایه از قبیل ابزارهای پوشش ریسک نیز می تواند در این فاینکس به مردم معرفی شود ، از طرفی هم فرصت مناسبی است تا عموم مردم نیز با سازو کار بورس های کالایی آشنایی بیشتری پیدا کنند.

به گفته سلطانی نژاد، از طرفی در سال های اخیربورس های کالایی ما حرکتی را به سمت محوریت اشخاص به خصوص اشخاص حقیقی در بازار سرمایه و بازارهای کالایی داشته اند که به نظر می رسد معرفی روش فعالیت این اشخاص در بورس های کالایی نیز بتواند یکی از دستاوردهای این نمایشگاه باشد. همچنین بحث تامین مالی منابع به ویژه منابع خرد و جهت دهی آن برای فعالیت های اقتصادی می تواند در این نمایشگاه بورس، بانک و بیمه معرفی خواهد شد.

وی در پاسخ به این سوال که هدف بورس کالای ایران بورس کالای ایران از شرکت در این نمایشگاه چیست گفت:بورس کالا نیز با شرکت در نمایشگاه فاینکس ۲۰۱۷ در ابتدا سعی می کند به آموزش افرادی که در غرفه حضور پیدا می کند بپردازد و آنها را با نحوه داد و ستد معاملات آشنا کند بر همین اساس نیز برنامه هایی را در نظر گرفته ایم ومحتوا های آموزشی طراحی شده تا افراد بتوانند در فضای مجازی با نحوه انجام معاملات بیشتر آشنا شوند و آموزش ببینند تا بتوانند در فضای واقعی و کسب و کار خودشان هم از ابزارهایی که در مکانیزم بورس کالا استفاده شد بهره مند شوند.

به گفته مدیر عامل بورس کالای ایران، در سال های اخیر ابزارهای مالی چه در زمینه تامین مالی و چه پوشش ریسک توسعه پیدا کردند به این ترتیب در نمایشگاه بورس، بانک و بیمه و در غرفه بورس کالای ایران، این ابزارهای مالی و نحوه استفاده از آن ها برای کسانی که متقاضی نحوه آشنایی انجام معاملات هستند از طریق کلاس های آموزشی ، آموزش داده خواهد شد.

سلطانی نژاد تاکید کرد: به طور کلی ابزارهای مالی نیازمند آموزش هستند به ویژه برای کسانی که می خواهند در عرصه بازار مالی فعالیت های حرفه ای داشته باشند، بنابراین باید به طور حتم آموزش های لازم را ببینند، البته ابزارهای دیگری نیز وجود دارد که عموم مردم می توانند از آن استفاده کنند و دوره های آموزشی ویژه سطوح مختلف اعم از پیشرفته و عادی توسط بورس کالا در نمایشگاه ارائه خواهد شد.

سلطانی نژاد در پایان اشاره کرد: بورس کالای ایران در سال های ابتدایی فعالیت خود محلی برای ارتباط بنگاه ها با یکدیگر بوده، اما خوشبختانه با سیاست هایی که اتخاذ شده به سمت فعالیت اشخاص حقیقی و نهادهای خرد نیز حرکت کرده و اکنون فضایی ایجاد شده تا سرمایه گذاران خرد، کشاورزان و سایر فعالانی که در واقع به نوعی بنگاه های تخصصی محسوب نمی شوند هم در این بورس فعالیت کنند

آخرین وضعیت مس جانجا به روایت مدیرعامل «تجلی»

پروژههای تجلی در مسیر پیشرفت/ عملیات اجرایی احداث کارخانه ۱۳۰ هزار تنی کنسانتره مس جانجا کلید خورد

فراخوان شناسایی متقاضیان همکاری با فولاد مبارکه منتشر شد

اتمام آنومالی شمالی معدن چادرملو تا پایان سال ۱۴۰۴/ برای معادن T۱ و T۲ نیازمند روش استخراج زیرزمینی هستیم

«سیاوش عبدی» مشاور مدیرعامل، مدیر گروه روابط عمومی و حوزه مدیرعامل شد

نخستین رویداد "چادرو" به کار خود پایان داد

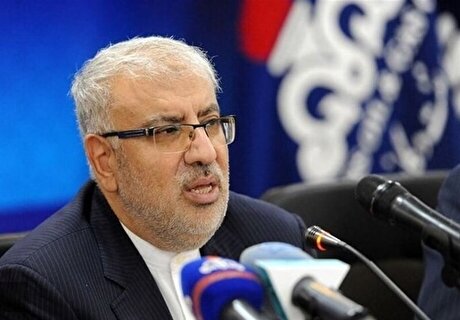

۷۲ هزار میلیارد تومان از بدهی تولیدکنندگان برق پرداخت شد

اولین جلسه مدیریت شرکت با حضور مدیرعامل جدید گروه ملی

نوچاد، سکوی سرمایهگذاری برای کسبوکارهای نوپا و فناورانه

بیستوهشتمین نمایشگاه نفت تا دقایقی دیگر آغاز به کار میکند

ناوگان حملونقل باید تا ۵ سال آینده برقی شود

قیمت روز ارزهای مبادله ای/ دلار ثابت ماند

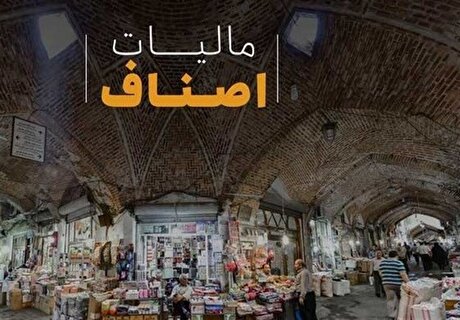

۵ مزیت استفاده از تبصره ماده ۱۰۰ مالیاتی برای اصناف

خرید دلاری مسکن یعنی خروج ارز از کشور/ با متخلفان برخورد شود

قانون بر زمین مانده تجمیع اطلاعات اکتشافی

شناسایی ۳۰ هزار خانه خالی در شهرهای جدید

رشد ۶۰ درصدی تولید نفت در دولت سیزدهم

ضرورت تکمیل زنجیره ارزش در مس؛ تولیدات فعلی نیمهخام است

کاهش ۱۴ درصدی سود خالص آرامکوی عربستان

پس از اصلاح ساختار مالی، بهدنبال اصلاح ساختار تولید هستیم

«سیداحمدرضا صدر» سرپرست روابط عمومی سازمان توسعه و نوسازی معادن و صنایع معدنی ایران (ایمیدرو) شد

گزارش تصویری از بازدید اصحاب رسانه از معدن و واحد دیسپچینگ مجتمع معدنی چادرملو

اختتامیه نخستین رویداد چادرو - گزارش تصویری (۲)

اختتامیه نخستین رویداد چادرو - گزارش تصویری (۱)

جیانپیترو بندتی، کارآفرین ۸۱ ساله درگذشت

برقراری تجارت آزاد بین ایران و اوراسیا تا ۲ ماه آینده

آخرین وضعیت مس جانجا به روایت مدیرعامل «تجلی»

صادرات ۱.۳ میلیون تنی فولاد خوزستان در سال گذشته