سرویس خبر : معادن و مواد معدنی

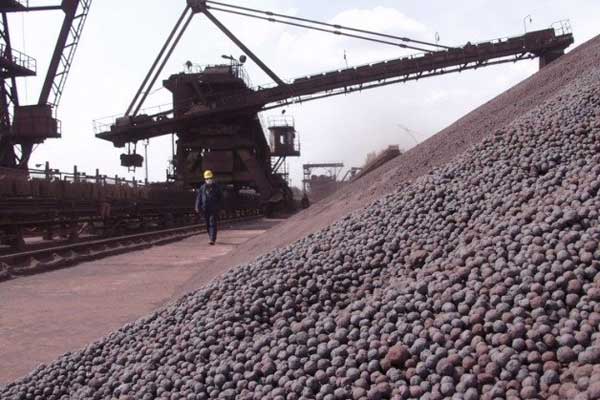

سنگ آهن در بنادر چین به کمتر از 60 دلار رسید

می متالز - سنگ آهن وارداتی در چین باز هم کاهش یافت و در بنادر قیمت به کمتر از 60 دلار هر تن سی اف آر نیز رسیده است. بیلت در بازار چین 10 دلار ارزان تر شده 413 دلار هر تن شده است.

در بازار سنگ آهن تقاضا کم شده کارخانه ها به جای خرید به فکر فروش محموله های سنگ آهن انبارها هستند.

موجودی سنگ آهن 42 بندر اصلی چین 136.15 میلیون تن ثبت شده که 3.26 میلیون تن نسبت به هفته قبل بالا رفته است. البته فعالان بازار معتقد نیستند رشد موجودی بنادر موجب افت قیمت شده چون چند ماه است موجودی بالای 130 میلیون تن قرار دارد.

برخی معتقدند افت قیمت دیگر متوقف شده و روزهای آتی بهبودهایی مشاهده خواهد شد.

بی اچ پی بیلیتون روزهای اخیر سنگ آهن خلوص 62 درصد خود را در 61.3 دلار هر تن سی اف آر به چین فروخت. خلوص پایین تر در 59.3 دلار نیز معامله شد.

منبع: ایفنا

عناوین برگزیده

پنج ساعت پیش

یک روز پیش

دو روز پیش

طلای جهانی از تکاپو افتاد

بازار طلای جهانی اندکی سرد شد

صنعت فولاد ایران هدف جدیدترین تحریمهای آمریکا

ارزش سهام شرکت فولاد اقلید ۴ برابر شد

ساخت ابر پروژه فولاد استان همدان با ۳۰ هزار میلیارد ریال سرمایهگذاری

جزئیات پیشرفت پروژه عظیم مجتمع مس جانجا اعلام شد

«تجلی» همچنان بر مدار توسعه/ آخرین خبرها از اولین شرکت پروژهمحور بورس

انعقاد قرارداد همکاری مشترک هلدینگ تجلی با دانشگاه شهید بهشتی

تعدیل نیرو در کارخانه فروآلیاژ ازنا ناشی از افزایش تعرفه برق است

پورمختار: مراکز پژوهشی، راهکارهای عملی برای مشارکت مردم در جهش تولید ارائه کنند

افتتاح همزمان ۱۶ نیروگاه خورشیدی در ۶ استان کشور

مدیرعامل شرکت ملی مناطق نفتخیز جنوب تأکید کرد

ضرورت روزآمدسازی دانش و اطلاعات مدیران مناطق نفتخیز جنوب

با حکم معاون وزیر نفت در امور پتروشیمی

مدیر شرایط اضطراری و بحران پتروشیمیهای منطقه ویژه پارس منصوب شد

کنترل و پایش خطوط تولید با نرمافزارهای بومی مبتنی بر هوش مصنوعی

خوشبینی پاکستان درباره تکمیل خط لوله گاز با ایران بهرغم هشدار آمریکا

رئیس سازمان نظام مهندسی استان تهران:

باید ساختمانهای باشکوه در ایران ساخته شود

بهبود پایداری شبکه برق فوق توزیع منطقه دشت آزادگان

فروش اطلس، کوییک، شاهین، سهند و ساینا به قیمت کارخانه

شعار امسال با انسجام جامعه کارگری محقق خواهد شد

«تجلی» همچنان بر مدار توسعه/ آخرین خبرها از اولین شرکت پروژهمحور بورس

وزیر صمت: شورای رقابت مسوول قیمت پژوپارس است

افزایش قابل توجه صادرات مواد معدنی ترکیه پس از اقدامات انجمن صادرکنندگان مواد معدنی دریای اژه

شتابدهندههای قیمت طلای جهانی کداماند؟/ اثر عوامل سیاسی و اقتصادی بر رشد فلز زرد

طلای جهانی از تکاپو افتاد

جزئیات پیشرفت پروژه عظیم مجتمع مس جانجا اعلام شد

افتتاح نخستین طرح پیشران اقتصادی کشور با سرمایهگذاری «ومعادن»

ضرورت جذب سرمایهگذاری مالی و مشارکت مردمی برای توسعه معادن

پورمختار: مراکز پژوهشی، راهکارهای عملی برای مشارکت مردم در جهش تولید ارائه کنند