رشد جهانی قیمت فولاد بر بازار ترکیه نیز اثر گذاشت

با نگاهی به وضعیت فولادسازان ترکیه، اینطور برداشت میشود که در 6 ماه آغازین سال 2017، تولید محصولات تخت فولادی در این کشور روند رو به رشدی را تجربه کرد. این در حالی است که مصرف محصول یاد شده در ترکیه کاهش یافت. باید خاطرنشان ساخت مصرف فولاد تخت در این کشور به 8.12 میلیون تن رسید؛ یعنی در 6 ماه مذکور، کاهش 6 درصدی را نسبت به مدت مشابه سال گذشته داشت. مقدار تولید محصولات فولادی یاد شده نیز در ترکیه در 6 ماه ابتدایی سال 2017، حدود 6.30 میلیون تن برآورد شد که نسبت به مدت مشابه سال 2016 با رشد 21 درصدی همراه بود.

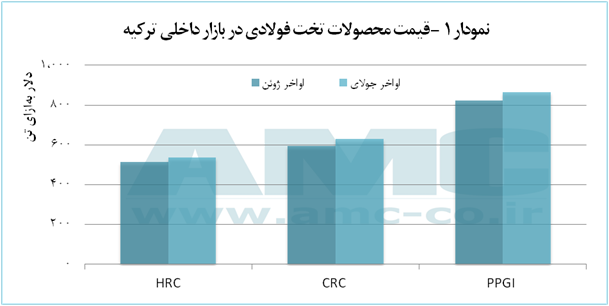

با نگاهی به بازار داخلی و تغییرات قیمت محصولات فولادی از انتهای ماه ژوئن تا انتهای ماه جولای، رشد قیمتی برای محصولات مختلف فولادی در بازار داخلی ترکیه مشهود است. نمودار 1 تغییرات قیمت برای ورقهای نورد گرم، ورقهای نورد سرد و ورقهای گالوانیزه رنگآمیزی شده در بازار داخلی ترکیه را نشان میدهد. همانطور که در نمودار پیداست، روند قیمت در یک ماه مورد بحث صعودی بود.

همانطور که در این نمودار مشاهده میشود، ورقهای نورد گرم (HRC) در روز جمعه 28 جولای سال 2017 با قیمتی در رنج بین 530 تا 540 دلار بهازای هر تن به فروش رسیدند. در حالی که این محصول در 4 هفته گذشته از آن، یعنی در تاریخ 30 ژوئن با قیمتی در رنج بین 510 تا 520 دلار بهازای هر تن به فروش رفت؛ بدین ترتیب میتوان گفت که در طول 4 هفته، قیمت هر تن ورق نورد گرم رشد 20 دلاری داشته است. همچنین گفتنی است قیمت هفتگی برای ورقهای نورد سرد (CRC) در بازار داخلی ترکیه در تاریخ 28 جولای معادل 620 تا 640 دلار برای هر تن گزارش شد.

در حالی که این محصول در انتهای ماه ژوئن با قیمتی بین 590 تا 600 دلار به فروش میرفت؛ یعنی حدودا بیش از 30 دلار در هر تن افزایش قیمت را تجربه کرد. همانطور که در نمودار نیز نشان داده شده، ارزیابی قیمت هفتگی برای هر تن ورقهای گالوانیزه رنگآمیزی شده (PPGI) در 28 جولای حدود 870 تا 860 دلار بود در حالی که محصول یاد شده در انتهای ماه ژوئن با قیمت 800 تا 845 دلار بهازای هر تن معامله میشد؛ در واقع میتوان گفت که قیمت این محصول در بازار ترکیه با رشد حدود 40 دلاری همراه بود.

روند صعودی قیمتها را باید ناشی از رشد تقاضا در بازار دانست. گفتنی است که تقریبا قیمت تمامی محصولات فولادی، از جمله بیلت و میلگرد در بازارهای جهانی با افزایش قیمت همراه بوده است. این افزاش قیمت در فولاد، قیمت کالاهای وابسته، همچون ضایعات و سنگ آهنرا نیز افزایش داد. بنابر عوامل تأثیرگذار در افزایش قیمتها، احتمال کاهش قیمتها در کوتاهمدت بسیار اندک خواهد بود.

فلز کمیابی که خواب را از چشم بایدن گرفته است

بازدید فرماندار و مسوولین اجرایی شهرستان سقز از روند اجرای پروژه ملی احداث کارخانه استحصال طلای سقز

تحقق شعار سال ۱۴۰۳، نیازمند ایجاد شرکتهای پروژهمحور است

اطلاعیه فرابورس برای واگذاری استقلال و پرسپولیس

دستورالعمل تنظیم بازار ورق گرم فولادی بازبینی میشود

مجلس بر اجرای متناسبسازی حقوق بازنشستگان مطابق با برنامه اصرار دارد

ثبت سه محدوده معدنی جدید توسط شرکت اکتشاف و حفاری صدرتامین

مراسم معارفه مدیرعامل شرکت ملی صنایع مس ایران برگزار شد

افتتاح نخستین طرح پیشران اقتصادی با سرمایهگذاری "ومعادن"/ سرمایهگذاری ۳.۵ میلیارد دلاری "ومعادن"

حمایت ۲.۵۵۰ همتی صندوق تثبیت بازار سرمایه از بازار سهام در فروردین ۱۴۰۳

پروژههای تجدیدپذیر باید از مسیر بازار سرمایه تامین مالی کنند/ بهرهگیری از ظرفیتهای بورس

بازار سرمایه، محلی برای رونق تولید و اشتغالزایی است/ بورس، اصلیترین بازار برای تامین مالی شرکتها

بهرهبرداری از طرح تکمیل آبرسانی به گرمسار و نیروگاه تجدیدپذیر خورشیدی

تغییرات مدیریتی با تمرکز بر اهداف فنی و توسعهای/ فسادستیزی اساس کار در ایمیدرو است

قدردان دغدغهمندی وزیر صمت درباره شرکت مس آذربایجان هستیم

رونمایی از ماشین خودران دامپتراک تولیدی یک شرکت دانشبنیان در سمنان

اولین جلسه مدیریت گروه ملی صنعتی فولاد ایران در سال ۱۴۰۳

۱۱ طرح صنعت آب و برق استان سمنان با حضور رییسجمهور بهرهبرداری شد

ثبت بالاترین میزان تاریخ تولید فولاد ایران در سال ۱۴۰۲

افتتاح بزرگترین کارخانه فروسیلیس ایران در دامغان طی سفر دولت سیزدهم

ثبت بالاترین میزان تاریخ تولید فولاد ایران در سال ۱۴۰۲

کشف یک تن شیشه از بار ۲۰ تنی سنگ معدن تریلی توقیفی

تحقق شعار سال ۱۴۰۳، نیازمند ایجاد شرکتهای پروژهمحور است

دستورالعمل تنظیم بازار ورق گرم فولادی بازبینی میشود

دومین رکورد تناژ تولیدی تاریخ فولاد اکسین شکسته شد

قیمت جهانی طلا امروز ۱۴۰۳/۰۱/۲۴

پروژههای تجدیدپذیر باید از مسیر بازار سرمایه تامین مالی کنند/ بهرهگیری از ظرفیتهای بورس

بازار سرمایه، محلی برای رونق تولید و اشتغالزایی است/ بورس، اصلیترین بازار برای تامین مالی شرکتها