نانوذرات مس به جنگ CO2 میروند

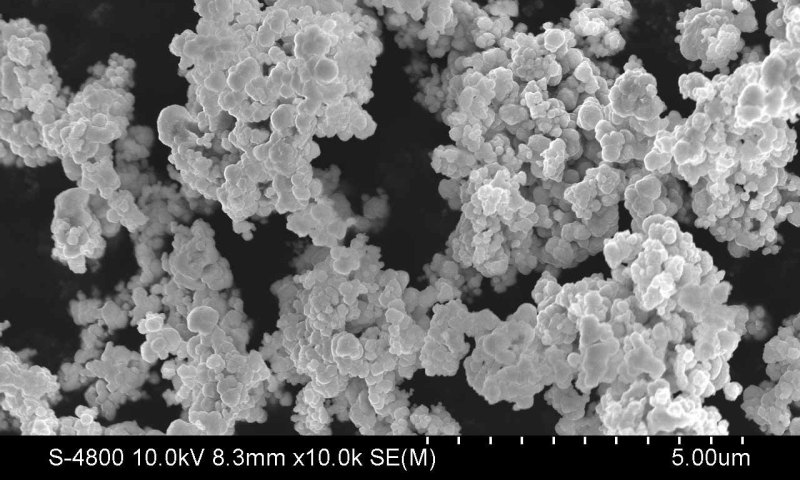

به گزارش می متالز، محققان LBL به سرپرستی «پیدونگ یانگ» (Peidong Yang)، دانشمند امریکایی، توانستهاند با الکتروکاتالیستی که از نانوذرات مس به دست آوردهاند، دیاکسیدکربن را بشکنند و از آن اتیلن، اتانول و پروپانول به دست آورند. نکته جالب در این پژوهش آن است که در روند تبدیل دیاکسیدکربن به مواد دیگر، انرژی بسیار کمی مصرف میشود. این یکی از آخرین تحقیقات LBL برای پیدا کردن راهحلهایی پاک برای استفاده از CO2 است.

براساس نتیجه این پژوهش که سپتامبر امسال در نشریه Proceedings of the National Academy of Sciences منتشر شده است مواد به دست آمده در این روند که همگی سه اتم کربن دارند، میتوانند در زندگی مدرن موارد استفاده زیادی داشته باشند.

اتیلن ماده اولیه ساخت وسایل پلاستیکی است که مهمترین آنها PVC است و در لولهکشی ساختمانها مورد استفاده قرار میگیرد. اتانول، که یکی از منابع تولید آن بیوماس (زیستتوده) است امروزه برای ساخت سوختهای سازگار با طبیعت مورد استفاده قرار میگیرد و بسیار محبوب است. پروپانول نیز یک نوع سوخت بسیار قوی است که هزینه ساخت آن بالاست و از همین رو پیدا کردن راهی برای تولید ارزان آن میتواند بسیار ارزشمند باشد.

در سالهای اخیر تلاشهای تحقیقاتی برای کاهش دیاکسیدکربن در حوزه انرژی بسیار زیاد شدهاند. بسیاری از این تحقیقات در تلاش هستند تا از تولید دیاکسیدکربن بیشتر جلوگیری کنند. اما تحقیق حاضر در تلاش است دیاکسیدکربن موجود را به موادی تبدیل کند که خود در دیاکسیدکربن کمتری تولید میکنند.

مقاله تحقیقاتی پیدونگ یانگ و همکاران را میتوانید اینجا بخوانید.

فلز کمیابی که خواب را از چشم بایدن گرفته است

بازدید فرماندار و مسوولین اجرایی شهرستان سقز از روند اجرای پروژه ملی احداث کارخانه استحصال طلای سقز

تحقق شعار سال ۱۴۰۳، نیازمند ایجاد شرکتهای پروژهمحور است

مجلس بر اجرای متناسبسازی حقوق بازنشستگان مطابق با برنامه اصرار دارد

افزایش ۹ درصدی تولید سالانه در منطقه ویژه اقتصادی خلیج فارس

ثبت سه محدوده معدنی جدید توسط شرکت اکتشاف و حفاری صدرتامین

"ومعادن" با رشدی ۳۳ درصدی بهای تمام شده سرمایهگذاریهای خود به استقبال سال جدید رفت

افزایش تولید ۱۶ درصدی «گندله» و ۹ درصدی «کنسانتره» سنگ آهن شرکتهای بزرگ

ثبت سومین رکورد تولید روزانه آهن اسفنجی در فولاد هرمزگان

جزئیات تسهیلات ۲۰۰ هزار میلیارد تومانی اشتغال در ۱۴۰۳

قیمت جهانی طلا امروز ۱۴۰۳/۰۱/۲۸

قیمت جهانی نفت امروز ۱۴۰۳/۰۱/۲۸ |برنت ۹۰ دلار و ۷۲ سنت شد

کارکرد فناوریهای نو در معادن

افزایش قیمت روی با کاهش موجودی انبارها

لزوم همراهی دولت با فعالان بخش معدن

توسعه سبد محصولات برای ارتقای سهم صادراتی جهان فولاد سیرجان

چهارمین کنفرانس بینالمللی فولادسازی و ریختهگری در فولاد هرمزگان برگزار میشود

جلسه مدیریت بحران فولاد هرمزگان برگزار شد

از برنامه انتقال پساب به کارخانه کنسانتره تا انتقال باطلهها به کورههای آجرپزی

تحقق شعار سال ۱۴۰۳، نیازمند ایجاد شرکتهای پروژهمحور است

دومین رکورد تناژ تولیدی تاریخ فولاد اکسین شکسته شد

قیمت جهانی طلا امروز ۱۴۰۳/۰۱/۲۴

آگهی فراخوان عمومی "طرح افزایش ایمنی و بهینهسازی تابلوهای موجود MV سایت کارخانه احیاء مستقیم شرکت جهان فولاد سیرجان" - شماره مناقصه: ۱۷-۰۳-ک-م

عملکرد بیسابقه فولاد آلیاژی ایران در سال ۱۴۰۲

مشکلی برای تأمین ارز نخواهیم داشت

افزایش ۹ درصدی تولید سالانه در منطقه ویژه اقتصادی خلیج فارس

ثبت رکورد برای اقتصاد چین

حراج شمش طلا پس از ۱۱ سال تعلیق در ویتنام