سبقت رشد تقاضای آلومینیوم از عرضه، آینده روشن است

به گزارش می متالز، قیمت آلومینیوم طی سالجاری، عمدتاً تحتتأثیر عوامل بنیادین از رشد بسیار خوبی در بورس فلزات لندن برخوردار شد؛ بهطوری که میتوان گفت در بین فلزات پایه، تقریبا بهترین عملکرد را در این بازار از خود نشان داد. مهمترین عوامل رشد قیمت آلومینیوم طی این دوره، برنامهها و سیاستهای چین برای کاهش ظرفیت مازاد صنایع مختلف و مبارزه با آلودگی هوا بوده است. این امر منجر به ایجاد نگرانیها در بازار برای تنگتر شدن فاصله بین عرضه و تقاضاشده تا جاییکه حتی برخی از مؤسسات، کسری عرضه را برای سال جاری پیشبینی کردند.

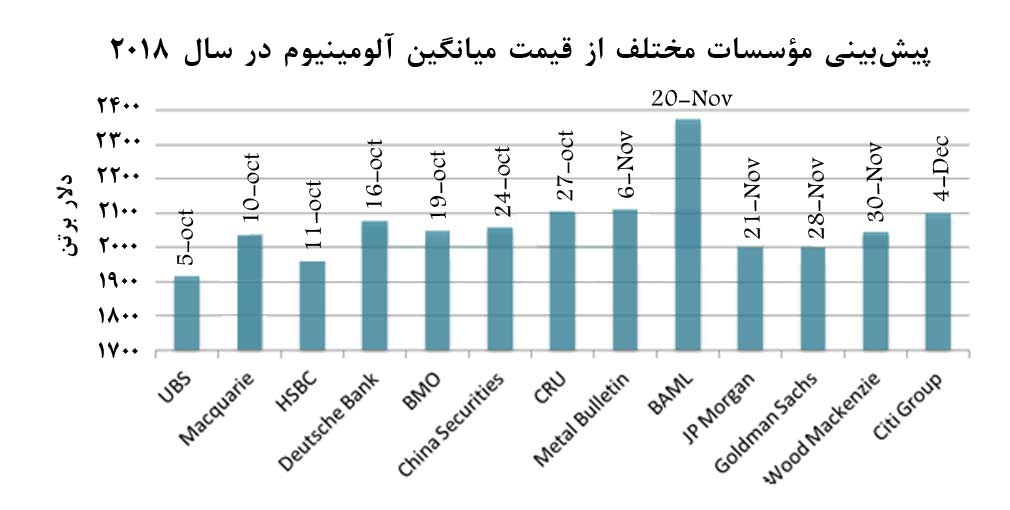

نمودار، پیشبینی قیمت میانگین آلومینیوم را ازسوی مؤسسات تحقیقاتی مختلف برای سال ۲۰۱۸ نشان میدهد. همانطور که در این نمودار مشاهده میشود، پیشبینیهای قیمتی هر مؤسسه براساس زمان انتشار آن مرتب شده است. این درحالی است که عمده مؤسسات پیشبینی خود را در نزدیکی رقم ۲.۰۵ هزار دلار بر هر تن ارایه کردهاند. گرچه در این بین مؤسسه BAML با پیشبینی ۲ هزار و ۳۷۵ دلار بهازای هر تن، بیشترین مقدار را برای قیمت معاملات نقدی آلومینیوم در سال آتی متصور شده است. با صرف نظر کردن از پیشبینی این مؤسسه که اختلاف زیادی با سایر مؤسسات دارد، بررسی پیسبینی مؤسساتی که نظر خود را در ماه نوامبر ارایه دادهاند، عمدتا نشان میدهد میانگین سطح قیمتی کمتری را برای آلومینیوم در سال آتی نسبت به سایر مؤسساتی که در ماه اکتبر اقدام به پیشبینی کردند، دارند. با توجه به دادههای ارایه شده در نمودار، متوسط مقادیر پیشبینی شده از سوی مؤسسات مختلف (به غیر از BAML) مقداری کمتر از ۲.۰۴ هزار دلار بر تن را نشانمیدهد.

با توجه به اینکه قیمت میانگین آلومینیوم در سال جاری (از ابتدای سال تا ۱۵ دسامبر) در حدود یک هزار و ۹۶۳ دلار بهازای هر تن است، میتوان گفت که تقریبا تمامی مؤسسات، به غیر از UBS و HSBC، بهواسطه افزایش تقاضای آلومینیوم و کند شدن رشد عرضه در سال آتی، مقدار میانگین قیمت بیشتری را نسبت به سال جاری پیشبینی کردهاند. انتظار میرود که میزان تقاضای آلومینیوم در سال آتی با ۵ درصد رشد نسبت به سال جاری مواجه باشد. این در حالی است که در سال جاری و سال آینده، از بسیاری از پروژههای توسعهای افزایش ظرفیت در چین ممانعت و جلوگیری شده است.

در چین، از بین ۲۵ پروژه توسعهای و پروژههای احداث ظرفیت جدید، مجوز بهرهبرداری از ۴ میلیون تن ظرفیت تولید آلومینیوم صادر شده که انتظار میرود تا پایان سال به مرحله عملیاتی برسد که از این میزان، تنها ۱.۲ میلیون تن ظرفیت جدید، متعلق به شرکت دولتی تولیدکننده آلومینیوم در چین، چالکو است. در مورد سال ۲۰۱۸، در مجموع ۱۸ پروژه احداث ظرفیت جدید در چین با مجموع ظرفیت ۳.۲ میلیون تن لحاظ شده است که از این بین حدود دوسوم آن متعلق به شرکتهای دولتی، نظیر چالکو، است.

افتتاح نخستین طرح پیشران اقتصادی با سرمایهگذاری "ومعادن"/ سرمایهگذاری ۳.۵ میلیارد دلاری "ومعادن"

اطلاعیه فرابورس برای واگذاری استقلال و پرسپولیس

افتتاح بزرگترین کارخانه فروسیلیس ایران در دامغان طی سفر دولت سیزدهم

«فصبا» ۷۰ تومان سود تقسیم کرد

قیمت جهانی طلا امروز ۱۴۰۳/۰۱/۲۹

طلای جهانی از تکاپو افتاد

بازار طلای جهانی اندکی سرد شد

صبا فولاد خلیج فارس «فصبا» ۷۰ تومان سود تقسیم کرد/ پروژه احیای مستقیم «فصبا» سال ۱۴۰۵ به بهرهبرداری میرسد

درج شرکت آلیاژ گستر هامون در بازار دوم فرابورس ایران

«تجلی» همچنان بر مدار توسعه/ آخرین خبرها از اولین شرکت پروژه محور بورس

رشد تولید سه ماهه ۲۰۲۴ فولاد خام ایران به ۱۶.۳ درصد رسید

فقر معادن در گیلان و تجارت پرسود "شن و ماسه"

رکوردشکنی فراتر از ظرفیت اسمی و عملیاتی

توضیح رئیس سازمان صمت تهران درباره افزایش قیمت لوازم خانگی

آیین رسمی واگذاری پرسپولیس و استقلال آغاز شد

همه سیاستهای ترامپ به نفع نفت آمریکا نیست

سمنان نیازمند نیروی کار است

لزوم ساماندهی نیروهای شرکتی و حفظ امنیت شغلی کارگران

رشد اقتصادی روسیه رقم خورد

وزیر صمت: شورای رقابت مسوول قیمت پژوپارس است

جزئیات پیشرفت پروژه عظیم مجتمع مس جانجا اعلام شد

افتتاح نخستین طرح پیشران اقتصادی کشور با سرمایهگذاری «ومعادن»

ضرورت جذب سرمایهگذاری مالی و مشارکت مردمی برای توسعه معادن

افتتاح بزرگترین کارخانه فروسیلیس ایران در دامغان طی سفر دولت سیزدهم

ثبت بالاترین میزان تاریخ تولید فولاد ایران در سال ۱۴۰۲

«تجلی» همچنان بر مدار توسعه/ آخرین خبرها از اولین شرکت پروژه محور بورس

توضیح رئیس سازمان صمت تهران درباره افزایش قیمت لوازم خانگی

آیین رسمی واگذاری پرسپولیس و استقلال آغاز شد