بررسی عملکرد بزرگترین تولیدکنندگان پالادیوم در جهان

به گزارش می متالز، امروزه صنعت خودرو بزرگترین مصرفکننده فلزات پلاتینی محسوب میشود. عمده مصرف این فلزات در مبدلهای کاتالیزوری اگزوز وسایل نقلیه برای کاهش آلودگی است. انتظار میرود که تولید خودروهای پاک در سالهای آتی، افزایش یابد که به همان نسبت میزان تقاضا برای گروه فلزات پلاتینی نیز افزایش خواهد یافت.

شایان ذکر است که کشورهای محدودی جزو تولیدکنندگان فلزات پلاتینی هستند؛ آفریقای جنوبی و روسیه بهعنوان بزرگترین عرضه کنندگان این فلزات محسوب میشوند، اگرچه چند کشور دیگر نیز در رتبهبندی پس از آنها قرار میگیرند. در ادامه لیستی از 5 تولیدکننده برتر پالادیوم بر اساس دادههای سازمان زمین شناسی ایالات متحده در سال 2017 ارایه میشود.

روسیه

تولید معدنی پالادیوم روسیه در سال 2016 چیزی حدود 82 تن بوده است به طوری که با افزایش تولید معدنی پالادیوم از 81 تن به 82 تن گوی سبقت را از آفریقای جنوبی ربود. روسیه در سال 2016 بیشترین تولید پالادیوم را در جهان داشته است، البته در آن زمان مقدار تولید معدنی آفریقای جنوبی از 83 تن در سال 2015 به 73 تن در سال 2016 کاهش یافته بود.

شرکت Norilsk Nickel قبلا اعلام کرده بود که قصد دارد تا سال 2017 چیزی حدود 2.6 تا 2.7 میلیون اونس (معادل 74 تا 77 تن) پالادیوم از مواد اولیه در روسیه تولید کند.

آفریقای جنوبی

آفریقای جنوبی یکی از تولیدکنندگان اصلی پالادیوم در جهان است. تولید پالادیوم در سال 2016 برای آفریقای جنوبی 73 تن بوده است. این کشور بزرگترین ذخایر شناخته شده فلزات پلاتینی را به میزان 63 هزار تن در اختیار دارد.

آفریقای جنوبی به علت کاهش قیمت فلزات گروه پلاتین (از جمله پالادیوم) در اواخر سال 2015 و اوایل 2016، در کنار کم شدن مصرف و نیز توسعه فرایندهای استخراج، میزان تولید فلزات پلاتینی خود را در سال 2016 به میزان یک درصد کاهش داد. البته نکته جالب توجه آن است که تولید فلزات پلاتینی آفریقای جنوبی از سال 2011 تا 2016 به میزان 13 درصد کاهش یافته است.

زیمبابوه

10 تن از پالادیوم جهان را در سال 2016 کشور زیمبابوه تولید کرده است. شرکتZimplats بزرگترین تولیدکننده فلزات گروه پلاتین در این کشور است که البته 87 درصد از سهام آن متعلق به شرکت Impala Platinum Holdings آفریقای جنوبی است که در قسمت عظیمی از معادن زیمبابوه سهم دارد. شایعات اخیر مبنی بر این که دولت زیمبابوه قصد دارد بعضی از معادن تحت اختیار این شرکت را تصاحب کرده و آن را به شرکتهای جدید واگذار کند، زنگ خطری برای شرکتهای آفریقای جنوبی محسوب میشود. سود شرکتImpala Platinum Holdings برای سال 2016 تا 31 دسامبر به 21 میلیون دلار رسید و انتظار میرود که بهدلیل افزایش فروش فلزات پلاتینی، این میزان سوددهی نیز افزایش یابد.

کانادا

کانادا تولید پالادیوم خود را در سال 2016 به 23 تن رساند. تولیدات بالای پالادیوم کانادا باعث میشود که این کشور در بازار فلزات پلاتینی نقش فعالی داشته باشد. همچنین برخی منابع خبر از اکتشافات ذخایر جدید در کانادا دادهاند. شرکت North American Palladium نیز یکی از تولیدکنندگان بزرگ پالادیوم در جهان است که معدن بزرگ آن یعنی Lac des Illos در استان انتاریو در کانادا واقع است. این شرکت از سال 1993 به تولید محصولات پرداخته است و در 3 ماهه دوم سال 2017، بالغ بر 50،222 اونس (معادل تقریبا 1.4 تن) پالادیوم تولید کرد که بهمیزان قابل توجهی بیشتر از سال گذشته است.

آمریکا

تولید پالادیوم در سال 2016 در کشور آمریکا 13.2 تن برآورد شد. شرکت معدنی استیلواتر (Stillwater) تنها تولیدکننده گروه فلزات پلاتینی در آمریکا بود تا اینکه در ماه می 2017 توسط شرکت معدنی Sibanye Gold واقع در کشور آفریقای جنوبی تصاحب شد. این معامله 2.2 میلیارد دلاری به شرکت Sibanye اجازه داد تا نفوذ خود در آمریکا را گسترش داده و وابستگی معادن آفریقای جنوبی را به شرکتهای آمریکایی کاهش دهد.

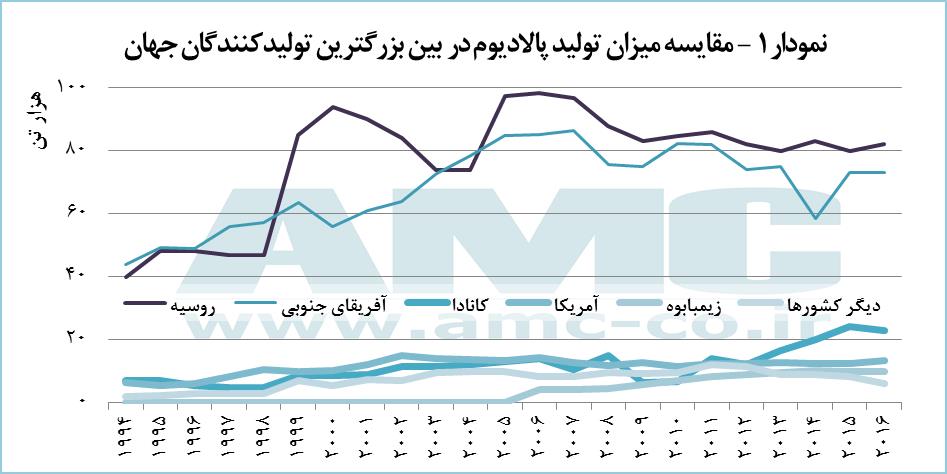

نمودار 1 حجم تولید پالادیوم توسط بزرگترین تولیدکنندگان جهانی را نشان میدهد. همانگونه که پیداست در 20 سال گذشته روسیه و آفریقای جنوبی بیشترین سهم تولید پالادیوم را از آن خود کردهاند. بهعلاوه پیداست که بهطور قابل ملاحظهای 5 کشور شرح داده شده، سهم بسیار بزرگی در تولید پالادیوم دارند و سهم سایر کشورهای جهان در مقابل مجموع تولید آنها بسیار ناچیز است.

افتتاح نخستین طرح پیشران اقتصادی با سرمایهگذاری "ومعادن"/ سرمایهگذاری ۳.۵ میلیارد دلاری "ومعادن"

اطلاعیه فرابورس برای واگذاری استقلال و پرسپولیس

قیمت جهانی طلا امروز ۱۴۰۳/۰۱/۲۹

بازار طلای جهانی اندکی سرد شد

کشف یک تن شیشه از بار ۲۰ تنی سنگ معدن تریلی توقیفی

افتتاح بزرگترین کارخانه فروسیلیس ایران در دامغان طی سفر دولت سیزدهم

«فصبا» ۷۰ تومان سود تقسیم کرد

صبا فولاد خلیج فارس «فصبا» ۷۰ تومان سود تقسیم کرد/ پروژه احیای مستقیم «فصبا» سال ۱۴۰۵ به بهرهبرداری میرسد

درج شرکت آلیاژ گستر هامون در بازار دوم فرابورس ایران

رکوردشکنیهای فولاد هرمزگان ادامه دارد/ ثبت رکورد جدید در تولید آهن اسفنجی

بهرهمندی صنایع از انرژیهای تجدیدپذیر با مدیریت مناسب

نقش هوش مصنوعی در صنعت فولاد

آغاز پذیرهنویسی چهارمین صندوق سرمایهگذاری املاک و مستغلات

کاهش سرمایهگذاری بخش املاک و مستغلات چین

ساختوساز در اوکراین صعودی ولی هنوز در سطوح پایین

نیاز بالای صنعت فولاد اروپا به هیدروژن برای کربنزدایی

کاهش تولید فولاد چین

صیانت از حقوق سرمایهگذاران با تثبیت قوانین و مقررات/ کاهش نرخ مالیات، تولید را رونق میدهد/ موانع کسبوکار تسهیل شود

افت ۵۵ درصدی واردات قراضه آهن به چین

وزیر صمت: شورای رقابت مسوول قیمت پژوپارس است

افتتاح نخستین طرح پیشران اقتصادی کشور با سرمایهگذاری «ومعادن»

ضرورت جذب سرمایهگذاری مالی و مشارکت مردمی برای توسعه معادن

افتتاح بزرگترین کارخانه فروسیلیس ایران در دامغان طی سفر دولت سیزدهم

ثبت بالاترین میزان تاریخ تولید فولاد ایران در سال ۱۴۰۲

کشف یک تن شیشه از بار ۲۰ تنی سنگ معدن تریلی توقیفی

بهرهمندی صنایع از انرژیهای تجدیدپذیر با مدیریت مناسب

آغاز پذیرهنویسی چهارمین صندوق سرمایهگذاری املاک و مستغلات

صیانت از حقوق سرمایهگذاران با تثبیت قوانین و مقررات/ کاهش نرخ مالیات، تولید را رونق میدهد/ موانع کسبوکار تسهیل شود