نقره داغ چند ساله بر پیکر قیمت نقره

به گزارش می متالز، بهطور کلی پیشبینی میشود که در سالهای آتی قیمت فلزات گرانبها همراه با رشد تکنولوژی و عواملی نظیر آن افزایش یابد. از جمله نقره با رسانایی الکتریکی فوقالعاده و خواص منحصر بهفرد، نقش ویژهای را در تولید محصولات الکترونیکی دارد. در ضمن افزایش استفاده از فناوریهای جدید و رشد مصرف نقره، علاوه بر افزایش ارزش آن انتظار میرود که کارآیی و بهرهوری معادن طی 10 سال آینده نیز افزایش یابد.

به گفته برخی کارشناسان قیمت چند سال اخیر نقره کمی به شوخی شبیه شده است و این در حالی است که قیمت دیگر فلزات افزایش زیادی داشته است. در این میان میتوان سرب را نام برد که از سال 2015 تاکنون افزایش قیمتی نزدیک به 2 برابر را تجربه کرده، در حالی که قیمت نقره در زمان مشابه تغییرات مثبت قابل توجهی نداشته است. بهعلاوه نقره باید بهعنوان یک فلز استراتژیک بهدلیل استفاده از آن در بسیاری از لوازم خانگی روزمره در نظر گرفته شود. در ضمن باید دانست که تولید نقره در سال های اخیر کاهش یافته است و بهتدریج در حال تبدیل شدن به محصولی نادر است.

نوسانات نقره در طول تاریخ

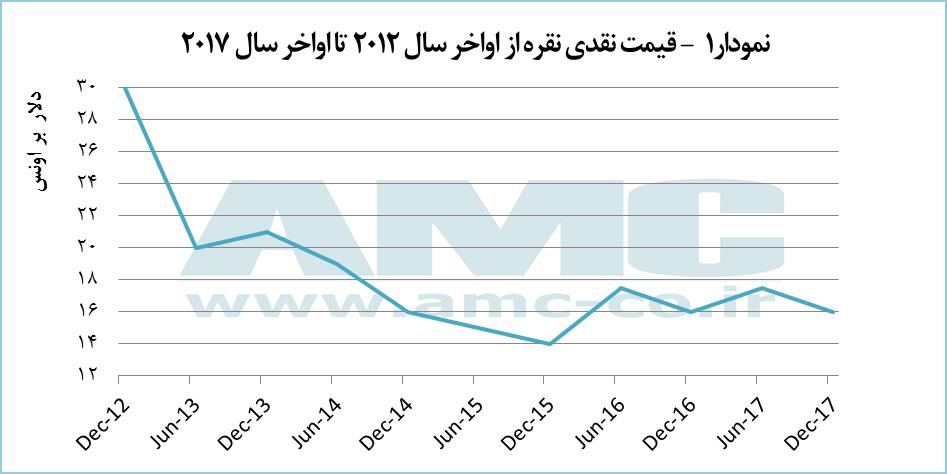

با نگاهی تاریخی به بازار نقره میبینیم که در بازار جهانی، بالاترین قیمت نقره در اوایل دهه 1970 کمتر از 2 دلار در هر اونس بود اما این فلز با ارزش در سال 1980، با جهشی چشمگیر، قیمتی در حدود 50 دلار بهازای هر اونس را تجربه کرد. پس از آن، قیمتها افت کرد و به کمتر از 10 دلار برای هر اونس بازگشت؛ بهنحوی که در دهه 90 میلادی قیمت میانگین نقره به حدود 5 دلار رسید. اما بار دیگر در سال 2011 و 2012 قیمت هر اونس نقره رشد زیادی کرد و به بیش از 30 دلار رسید. اما مجددا در سالهای اخیر قیمتها کاهش بسیاری یافته است؛ بهنحوی که در سال 2017، بالاترین قیمت برای نقره فقط 18.5 دلار برای هر اونس بوده است. نمودار 1 قیمت نقدی نقره را در 5 سال گذشته نشان میدهد، چنان که پیداست این فلز پس از کاهش قیمتها در سال 2013 رشد قیمت مؤثری را تا به امروز (اواخر سال 2017) مشاهده نکرده است.

در سال 2017 تا به امروز، میانگین قیمت فلز نقره برای هر اونس 17.30 دلار برآورد شده است و بر اساس پیشبینیهای صورت گرفته، در سال 2018 قیمت هر اونس این فلز با افزایش اندکی به حدود 17.80 دلار خواهد رسید. شواهد نشان میدهد که در 3 ماهه سوم سال 2019، قیمت هر اونس نقره بهطور متوسط 19.20 دلار خواهد بود. بهطور کلی، بهنظر میرسد که قیمت نقره با روندی کند در حال حرکتی رو به رشد است.

در پایان شایان ذکر است که بیشتر نقره دنیا از معادن سنگهای مس، سرب، مس - نیکل و سرب -روی در کشورهایی نظیر مکزیک، پرو، چین، استرالیا، شیلی و بولیوی حاصل میشود.

تحقق شعار سال ۱۴۰۳، نیازمند ایجاد شرکتهای پروژهمحور است

دستورالعمل تنظیم بازار ورق گرم فولادی بازبینی میشود

اطلاعیه فرابورس برای واگذاری استقلال و پرسپولیس

مجلس بر اجرای متناسبسازی حقوق بازنشستگان مطابق با برنامه اصرار دارد

افتتاح نخستین طرح پیشران اقتصادی با سرمایهگذاری "ومعادن"/ سرمایهگذاری ۳.۵ میلیارد دلاری "ومعادن"

مراسم معارفه مدیرعامل شرکت ملی صنایع مس ایران برگزار شد

قیمت جهانی طلا امروز ۱۴۰۳/۰۱/۲۹

دومین رکورد تناژ تولیدی تاریخ فولاد اکسین شکسته شد

کشف یک تن شیشه از بار ۲۰ تنی سنگ معدن تریلی توقیفی

ساخت ابر پروژه فولاد استان همدان با ۳۰ هزار میلیارد ریال سرمایهگذاری

پرونده قضایی برای پنج معدن شن و ماسه زرند تشکیل شد

صنعت فولاد ایران هدف جدیدترین تحریمهای آمریکا

ادامه رشد مصرف زغال سنگ علیرغم تعهدات انرژی پاک

قراضه آهن در کانال ۳۸۲ دلار جا خوش کرد

خبرنامه شماره ۱۳۷۲ فولاد منتشر شد

تداوم توفیقات جبهه حق در عرصههای امنیتی و اقتصادی

معامله ۴۰۸۴۸۴ تن ورق فولادی در بورس کالا طی هفته چهارم فروردین

دیدار مدیرعامل و مدیران شرکت آلومینای ایران با سردار مطهریزاده فرمانده نیروی انتظامی خراسان شمالی

شرکت آلومینای ایران موهبتی الهی است که به استان عرضه شده

افتتاح بزرگترین کارخانه فروسیلیس ایران در دامغان طی سفر دولت سیزدهم

ثبت بالاترین میزان تاریخ تولید فولاد ایران در سال ۱۴۰۲

کشف یک تن شیشه از بار ۲۰ تنی سنگ معدن تریلی توقیفی

تحقق شعار سال ۱۴۰۳، نیازمند ایجاد شرکتهای پروژهمحور است

دستورالعمل تنظیم بازار ورق گرم فولادی بازبینی میشود

دومین رکورد تناژ تولیدی تاریخ فولاد اکسین شکسته شد

نیسان به چاله رسید!

برای مردمی کردن اقتصاد چه باید کرد؟

بازار سرمایه با چالش مالیاتی در لایحه بودجه مواجه شده است؟