تداوم کاهش 2 درصدی تولید معادن مس جهان

به گزارش می متالز، تازه ترین گزارش گروه مطالعات بین المللی مس (ICSG) حاکیست: میزان تولید معادن مس جهان از ابتدای ژانویه تا پایان سپتامبر 2017 میلادی، به حدود 14 میلیون و 709 هزار و 200 تن رسید. رقم مدت مشابه سال 2016 میلادی، 15 میلیون و 64 هزار و 500 تن بود.

از این میزان، 8 میلیون و 85 هزار و 400 تن مربوط به قاره «آمریکا»، 3 میلیون و 122 هزار و 300 تن «آسیا»، یک میلیون و 414 هزار و 100 تن «آفریقا»، یک میلیون و 338 هزار و 500 تن «اروپا» و 748 هزار و 900 تن مربوط به «اقیانوسیه» بوده است.

در همین مدت، ظرفیت معادن مس جهان به 18 میلیون و 156 هزار تن رسید که نسبت به مدت مشابه سال گذشته (17 میلیون و 534 هزار تن)، حاکی از رشد 3.5 درصدی است.

بنا به این گزارش، تولیدکنندگان جهانی مس طی 9 ماهه سال جاری میلادی، 17 میلیون و 495 هزار تن مس تصفیه شده تولید کردند. این رقم طی مدت مشابه سال گذشته، 17 میلیون و 405 هزار تن بود که حاکی از افزایش 52 صدم درصدی این محصول در سال جاری میلادی است.

رشد بیش از 20 درصدی قیمت مس

بنا به این گزارش، قیمت جهانی مس به دلایلی نظیر تضعیف دلار، کاهش موجودی انبارها (حدود 30 درصد طی ماه های اخیر) و کمبود عرضه جهانی، به حدود 7105 دلار در تن رسیده است.

طلای جهانی از تکاپو افتاد

بازار طلای جهانی اندکی سرد شد

ارزش سهام شرکت فولاد اقلید ۴ برابر شد

صنعت فولاد ایران هدف جدیدترین تحریمهای آمریکا

ساخت ابر پروژه فولاد استان همدان با ۳۰ هزار میلیارد ریال سرمایهگذاری

جزئیات پیشرفت پروژه عظیم مجتمع مس جانجا اعلام شد

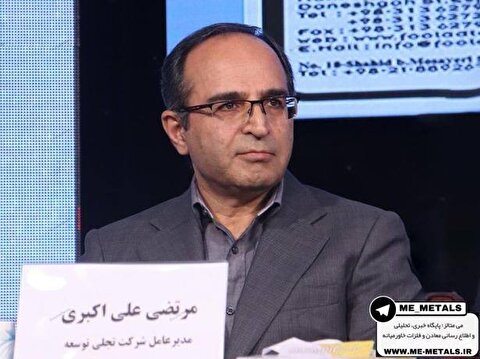

«تجلی» همچنان بر مدار توسعه/ آخرین خبرها از اولین شرکت پروژهمحور بورس

عید واقعی تجلی در سال ۱۴۰۳ اتفاق خواهد افتاد

انعقاد قرارداد همکاری مشترک هلدینگ تجلی با دانشگاه شهید بهشتی

انتصابات جدید در شرکت فولاد آلیاژی ایران

انتصابات جدید در شرکت فولاد آلیاژی ایران

گزارش تصویری از نشست مشترک هماندیشی مدیران عامل، اعضای هیات مدیره و معاونین شرکت فولاد مبارکه و گروه خودروسازی سایپا

همت والای کارگران زمینهساز تحقق شعار سال خواهد شد

ترس بازار کریپتو ریخت

تفاهم شرکت ملی صنایع مس و بانک شهر در راستای تامین مالی و توسعه صادرات

جریان گاز در مناطق سیلزده خراسان جنوبی و کرمان پایدار است/ اعزام تیمهای امداد برای خدمترسانی

مقرراتزدایی در نزدیکی کارآفرینها/ قانون هست اجرا خیر

تامین برق مراکز برگزاری آزمون سراسری با موفقیت انجام شد

بانکها حق تعطیل کردن بنگاهها را ندارند/ ۱.۲ میلیون نفر بیمه شدند

«تجلی» همچنان بر مدار توسعه/ آخرین خبرها از اولین شرکت پروژهمحور بورس

وزیر صمت: شورای رقابت مسوول قیمت پژوپارس است

افزایش قابل توجه صادرات مواد معدنی ترکیه پس از اقدامات انجمن صادرکنندگان مواد معدنی دریای اژه

شتابدهندههای قیمت طلای جهانی کداماند؟/ اثر عوامل سیاسی و اقتصادی بر رشد فلز زرد

طلای جهانی از تکاپو افتاد

بیتکوین آماده شد

فولاد هرمزگان بر مدار رکوردشکنی/ دومین رکورد تولید روزانه تختال به دست آمد

جزئیات پیشرفت پروژه عظیم مجتمع مس جانجا اعلام شد

افتتاح نخستین طرح پیشران اقتصادی کشور با سرمایهگذاری «ومعادن»