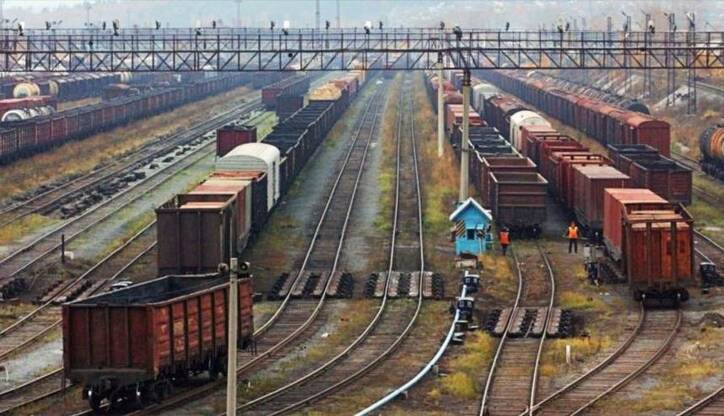

عملکرد راه آهن ایران به 45 میلیون تن رسید

به گزارش می متالز، غلامرضا نجفی اظهار کرد: بالغ بر 18 هزار میلیارد دلار حجم تجارتی که در دنیا اتفاق می افتد که از این میان حدود 17 هزار تن پتانسیل عبور حجم تجارتی از طریق ایران وجود دارد.

وی افزود: در حال حاضر راه آهن ایران 11 هزار کیلومتر خط دارد و به واسطه رشدهایی که در سال های متوالی داشته در سال جاری عملکرد راه آهن کشور به 45 میلیون تن می رسد و در نظر داریم با توجه به منابع و پشتوانه های موجود؛ سهم حمل و نقل ریلی از 12 درصد به 30 درصد افزایش پیدا کند.

مدیرکل بازرگانی بین الملل راه آهن جمهوری اسلامی ایران با بیان اینکه در حال حاضر 1500 کیلومتر خطوط ریلی در دستور کار قرار دارد، گفت: ایجاد اشتغال، افزایش امنیت، همبستگی و صلح میان کشورها و ارتقاء صادرات از مزایا و منافع ترانزیت ریلی است.

نجفی خاطرنشان کرد: در حال حاضر واگن های ایرانی نمی توانند به کشورهای مقاصد تجاری بروند و معمولا واگن هایی که از کشورهای(سی آی اس) به صورت ترانزیت به ایران می آیند و بار خود را تخلیه می کنند در بازگشت فرصتی برای صادرات را فراهم می کنند که واگن ها خالی برنگردند.

وی افزود: با سیاست گذاری هایی که توسط شرکت راه آهن جمهوری اسلامی ایران صورت گرفته و با سرمایه گذاری هایی که بخش خصوصی در حوزه راه آهن کشور انجام داده است سن ناوگان ریلی کشور کاهش می یابد.

مدیرکل بازرگانی بین الملل راه آهن جمهوری اسلامی ایران تصریح کرد: در کشور 27 سازمان در حوزه ترانزیت دخیل هستند که همه این فعالیت ها منجر به درآمد ارزی برای ایران می شود و قابل توجه است.

نجفی یادآور شد: از سال 1379 با توجه به فرموده مقام معظم رهبری در سیاست های کلی کشور؛ حمل و نقل ریلی به عنوان اولویت اول حمل و نقل مطرح شد و در برنامه ششم توسعه نیز به مزیت های حمل و نقل ریلی اشاره شده است.

وی گفت: تا سال 1392 سهم ترانزیت ریلی کشور روند کاهشی داشت اما از 92 تا 94 رشد 100 درصدی صورت گرفت و سال 95 مقداری کاهش پیدا کرد و در سال جاری دوباره روند افزایشی یافت و طبق تکلیف قانون باید سهم ترانزیت ریلی به 30 درصد برسد.

مدیرکل بازرگانی بین الملل راه آهن جمهوری اسلامی ایران اظهار کرد: 15 کشور همسایه ایران هستند و 8 مرز ریلی در کشور داریم که شاید کمتر کشوری این شرایط جغرافیایی و پتانسیل ریلی را داشته باشد و این موقعیت جغرافیایی فرصت های بسیاری را فراهم کرده که فقط با استفاده از کریدورهای شمال- جنوب عملی و محقق می شود.

نجفی بیان کرد: برای ترانزیت کالا از کریدور شمال- جنوب کم استفاده می شود در حالی که حدود 520 میلیارد یورو حجم تجارت چین با اروپا و حدود 77 میلیارد یورو حجم تجارت هند با اروپا است که تجارت این کشورها فرصت خوبی برای ترانزیت ایران فراهم می کند.

وی افزود: سالانه 30 میلیون تن حجم ترانزیت قابل عبور از ایران به صورت جاده ای و ریلی است و کشورهای(سی آی اس) می توانند از طریق دریای خزر به ایران و سپس با دریاهای آزاد ارتباط داشته باشند.

مدیرکل بازرگانی بین الملل راه آهن جمهوری اسلامی ایران با بیان اینکه کریدور شمال- جنوب به صورت ریلی بندر عباس را به بندر امیرآباد متصل می کند و فرصت بزرگی را در اختیار توسعه مازندران و کشور قرار می دهد، تصریح کرد: راه آهن از بابت منافع کلان و ملی قابل قیاس با حمل و نقل جاده ای نیست و همچنین راه آهن از لحاظ صرفه سوخت و حمل و نقل سبز نیز حائز اهمیت است.

فلز کمیابی که خواب را از چشم بایدن گرفته است

بازدید فرماندار و مسوولین اجرایی شهرستان سقز از روند اجرای پروژه ملی احداث کارخانه استحصال طلای سقز

تحقق شعار سال ۱۴۰۳، نیازمند ایجاد شرکتهای پروژهمحور است

اطلاعیه فرابورس برای واگذاری استقلال و پرسپولیس

مجلس بر اجرای متناسبسازی حقوق بازنشستگان مطابق با برنامه اصرار دارد

ثبت سه محدوده معدنی جدید توسط شرکت اکتشاف و حفاری صدرتامین

مراسم معارفه مدیرعامل شرکت ملی صنایع مس ایران برگزار شد

قیمت جهانی طلا امروز ۱۴۰۳/۰۱/۲۹

دومین رکورد تناژ تولیدی تاریخ فولاد اکسین شکسته شد

بهرهبرداری از طرح تکمیل آبرسانی به گرمسار و نیروگاه تجدیدپذیر خورشیدی

تغییرات مدیریتی با تمرکز بر اهداف فنی و توسعهای/ فسادستیزی اساس کار در ایمیدرو است

قدردان دغدغهمندی وزیر صمت درباره شرکت مس آذربایجان هستیم

رونمایی از ماشین خودران دامپتراک تولیدی یک شرکت دانشبنیان در سمنان

اولین جلسه مدیریت گروه ملی صنعتی فولاد ایران در سال ۱۴۰۳

۱۱ طرح صنعت آب و برق استان سمنان با حضور رییسجمهور بهرهبرداری شد

ثبت بالاترین میزان تاریخ تولید فولاد ایران در سال ۱۴۰۲

همت دولت در خدمت به مردم/ بهرهبرداری از دهها طرح اقتصادی و تصویب ۱۴۵ مصوبه جدید در سمنان

ضرورت تک نرخی شدن ارز برای پیشرفت صنعت فولاد کشور

تجلی؛ مسیر هموار مشارکت مردم در رشد تولید

افتتاح بزرگترین کارخانه فروسیلیس ایران در دامغان طی سفر دولت سیزدهم

ثبت بالاترین میزان تاریخ تولید فولاد ایران در سال ۱۴۰۲

تحقق شعار سال ۱۴۰۳، نیازمند ایجاد شرکتهای پروژهمحور است

دستورالعمل تنظیم بازار ورق گرم فولادی بازبینی میشود

دومین رکورد تناژ تولیدی تاریخ فولاد اکسین شکسته شد

قیمت جهانی طلا امروز ۱۴۰۳/۰۱/۲۴

اولین جلسه مدیریت گروه ملی صنعتی فولاد ایران در سال ۱۴۰۳

همت دولت در خدمت به مردم/ بهرهبرداری از دهها طرح اقتصادی و تصویب ۱۴۵ مصوبه جدید در سمنان

افتتاح نخستین طرح پیشران اقتصادی با سرمایهگذاری "ومعادن"/ سرمایهگذاری ۳.۵ میلیارد دلاری "ومعادن"